Cemen Tech

Cemen Tech is the world’s largest manufacturer of volumetric technology. Its concrete mixers are used in over 70 countries with customer success based on our cutting-edge technology, superior support, and the most innovative, versatile concrete production solutions available

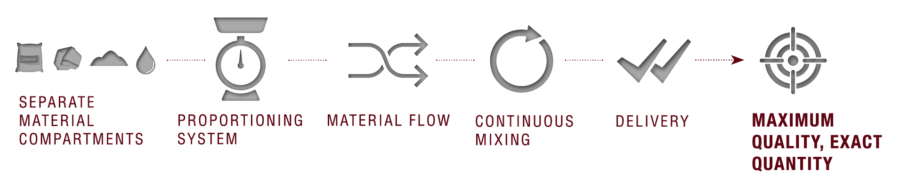

How do volumetric mixers work?

Volumetric concrete mixers give the operator complete control over their concrete - save time and money by mixing concrete on-site. Stop waiting for drum trucks, no short loads, no hot loads - pour exactly what is needed.

It's the perfect solution for utility projects, gunite & shotcrete, concrete delivery, paving & repair.

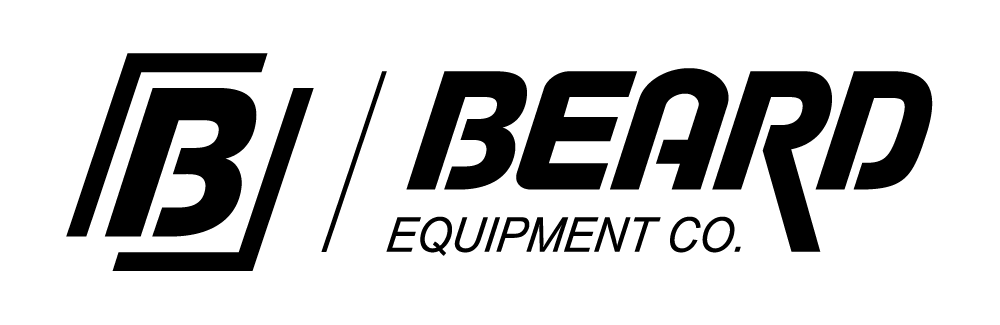

C Series

Cemen Tech’s new C Series mixers are the most innovative on the market today – batch, measure, mix, pour, record, and analyze jobs all-in-one unit.

Each mixer comes equipped with a state-of-the-art electronic control panel. The panel allows an operator in the field to track when a unit was in operation, how much concrete was poured, and the admixture used for each job. The information displays on a digital readout and also shows the exact use rate of aggregate, sand, water, and cement.

This mixer is the first volumetric concrete mixer to integrate with ACCU-POUR™. This suite of productivity solutions aims to help concrete producers expand and profitably grow their business. Job information is available with a few clicks for dispatchers while collected job data syncs between the mixer and office.

Benefits:

- Less cost and better quality than traditional drum mixing – accurate costs, precise mixtures and more uptime

- No “hot loads” or limited distance to jobs – separate materials storage on mobile unit ensures a fresh mix for maximum strength concrete on each job

- More time efficient – jobs can be done on-demand when your crew is ready for concrete, no need to go back to the plant to change applications or mixtures between jobs

- Consistently produce the exact mix design each and every time

- Less maintenance, on-site training and ongoing education from Cemen Tech team

- Eco friendly – less waste, less water, less carbon

Please call to discuss your equipment needs, request additional information or get an estimate today!

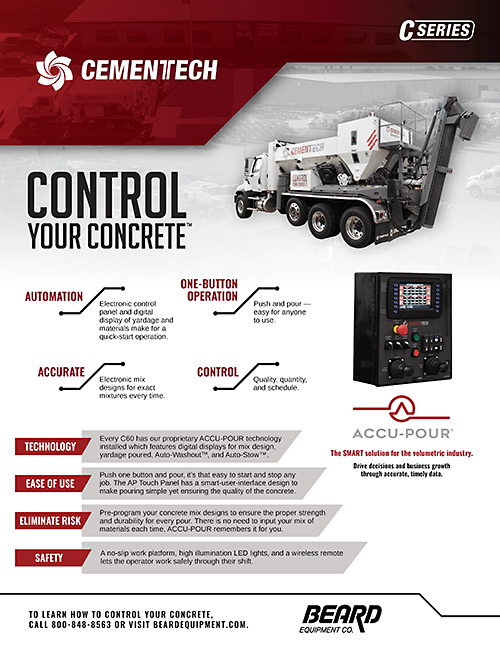

G Series

Cemen Tech’s G Series mixers are designed to meet the changing demands of gunite and shotcrete producers without sacrificing quality or performance.

Please call to discuss your equipment needs, request additional information or get an estimate today!

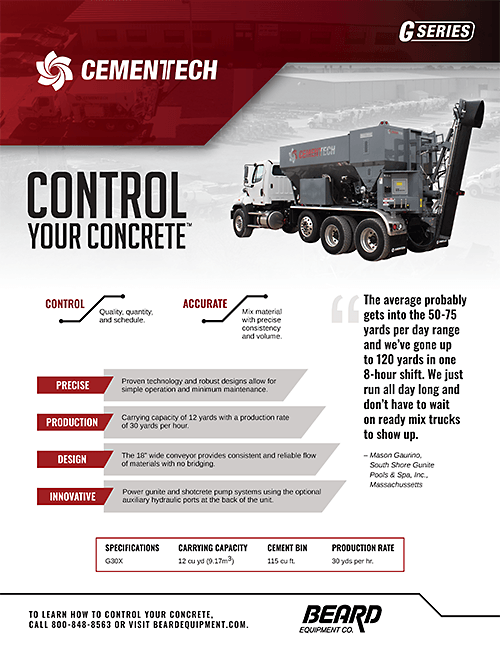

M Series

The M Series is Cemen Tech’s flagship unit of mobile concrete dispensers and the world’s most reliable concrete mixer with a proven track record of excellent performance, versatility and durability. These machines have continually led the industry with innovative improvements designed to meet customer objectives.

Key applications for the M Series meet all DOT standards and include general concrete, precast, flowable fill, pervious, rapid set and overlay concrete. This series has various options to fulfill any job you need done – pneumatic fill, dry color, liquid color, fiber chopper and latex.

Benefits:

- Less costly than traditional drum mixing – accurate costs, precise mixtures and more uptime

- No “hot loads” or limited distance to jobs – separate materials storage on mobile unit ensures a fresh mix for maximum strength concrete on each job

- More time efficient – jobs can be done on-demand when your crew is ready for concrete, no need to go back to the plant to change applications or mixtures between jobs

- Consistently produce the exact mix design each and every time

- Less maintenance, on-site training and ongoing education from Cemen Tech team

- Eco friendly – less waste, less water, less carbon

Please call to discuss your equipment needs, request additional information or get an estimate today!

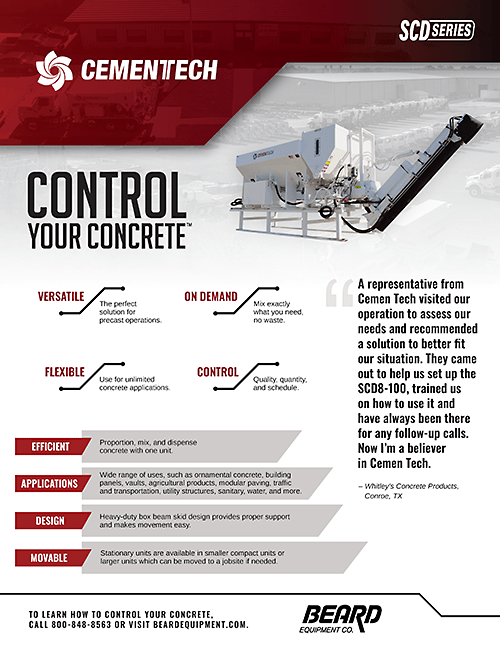

SCD Series | Stationary Mixers

Stationary mixers allow you the flexibility to produce concrete on your schedule to any mix design while eliminating overages. Our mixers are an ideal solution for precast concrete operations – store, proportion, mix and dispense concrete with a single machine.

Benefits:

- Store, proportion, mix and dispense concrete with one machine

- Compact size, easy to move

- Provide concrete production subject to your schedule

- Eliminate overages and shortages with precise measurements

- Consistently produce the exact mix design each and every time

- Less maintenance, on-site training and ongoing education from Cemen Tech team

- Eco friendly – less waste, less water, less carbon

Please call to discuss your equipment needs, request additional information or get an estimate today!

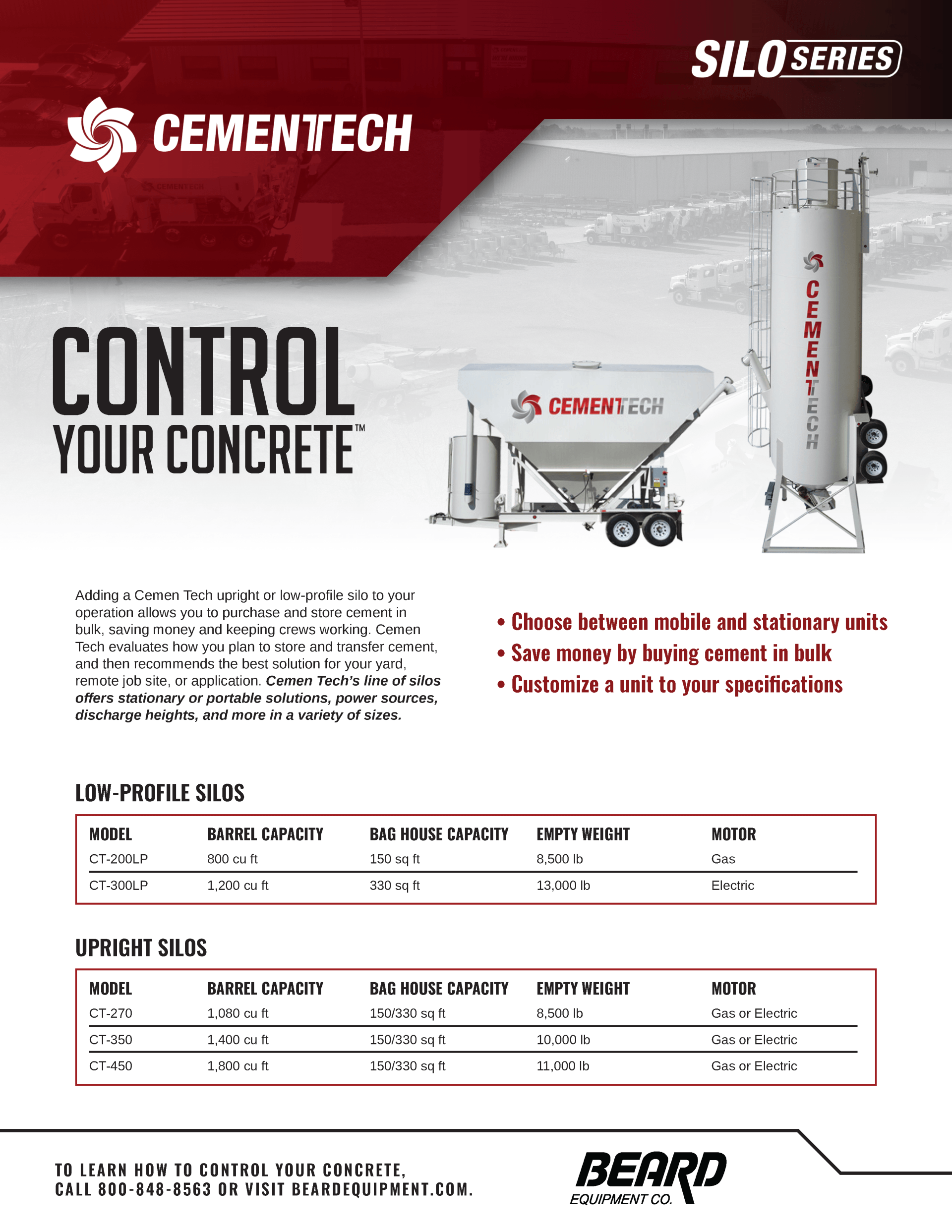

Cement Silos

Adding a Cemen Tech upright or low-profile silo to your operation allows you to purchase and store cement in bulk, saving money and keeping crews working. Cemen Tech evaluates how you plan to store and transfer cement, and then recommends the best solution for your yard, remote job site, or application. Cemen Tech’s line of silos offers stationary or portable solutions, power sources, discharge heights, and more in a variety of sizes.

- Choose between mobile and stationary units

- Save money by buying cement in bulk

- Customize a unit to your specifications

Please call to discuss your equipment needs, request additional information or get an estimate today!

Please visit

cementech.com for the complete range of Cemen Tech equipment and technologies.